- Home

- About Us

- Engineering Services

- News

- Video

- Career

- Contact

- Enquiry

- Locations We Serve

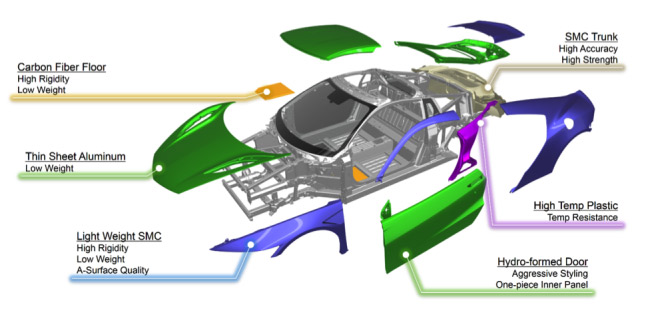

Nowadays, automotive industry is continuing to strive for light weight vehicle in improving fuel efficiency and emissions reduction. To produce a better performance car it is important to design vehicles with optimum weight.

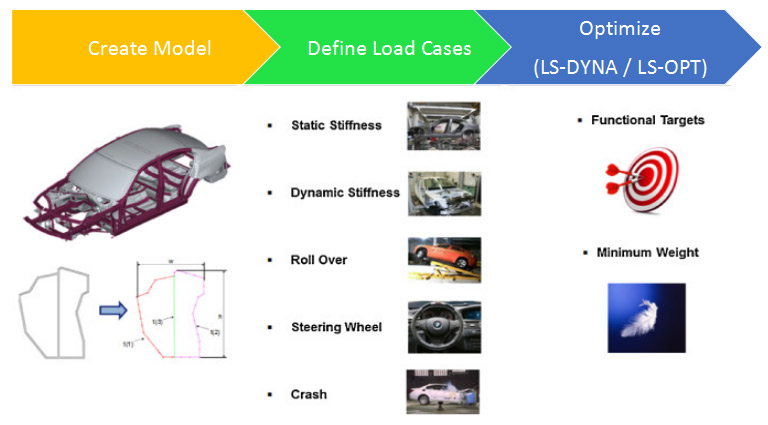

In order to reduce the weight of vehicle without sacrificing its integrity, ELENO energy aims to employ optimization techniques to propose an optimal design of an automotive component in early phase of product development.

Because FEM is a discretization method, the number of degrees of freedom of a FEM model is necessarily finite.

Advantages of CAE Techniques in optimization

Topology optimization : In topology optimization it is supposed that the element density can vary between 0 (void) and 1 (presence of the material). The variables are then given by the element-wise densities.

Topometry optimization : The idea behind topometry optimization is similar to that of topology optimization, the variables being the element-wise thicknesses. Of course this method does not apply to 3D elements where the concept of thickness is not applicable.

Topography optimization : Again, topography optimization can be applied only to 2D or shell elements, and aims at finding the optimum bead pattern in a component. Still, the concept is similar to the previous optimization types; simply speaking, the variables are given by the set of the element offsets from the component mid-plane.

Size optimization : Size optimization is the same as topometry optimization, but in this case the number of variables is greatly reduced in that the shell thicknesses of components are considered in place of the single elements of the domain.

Our setup is situated in Pune, Maharashtra, India and majorly we serve our customers from USA, Gulf Countries, UK ( United Kingdom ), Australia, Japan, European Countries, Belgium, UAE ( United Arab Emirates ), Israel, Turkey, Russia, Hungary, India