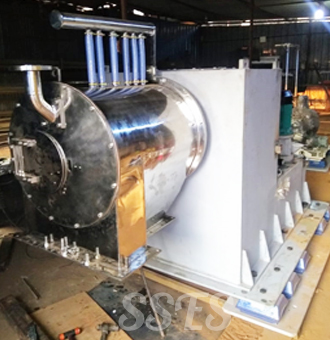

Soild collected on the screen and feed liquors drain through the pusher plates rotates with the basket and reciprocates on the forward stroke,the plate pushes solid along the screen,Consolidatingthe solids into a uniform cake.

On the reverse stroke,fresh screen is exposed and more slurry is deposited.Cake dries as it moves along the length of the screen and wash liquor may be applied to remove impurities.

Cake is pushed off the discharge end of the screen and directed to the collection chute.

- ABS, Ammonium Chloride, Ammonium Sulphate, Borax, Commom

- Salt, Cellulose Acetate, Ferrous

- Sulphate, Dichlorobenzene, Hydroquinone, Hexamine, Nickel

- Sulphate, Lithium compound, Nitrcellulose, Potassium

- Carbonate, Potassium Chloride, Sodium Chloride, Sodium

- Bicarbonate, Sodium Carbonate,Sodium Chlorate, Urea and any

- Crystalline Inorganic Salt.

- Process : Continous

- Solid Content : >25% by wt

- Average Particle Size : 80-2000 micron

- Solid throughput : 400 to 25000 kg/hr

- Soild Recovery : >98%

- MOC : As per Client Requirement

- High Product quality & increase performance through proper selection of the basket configuration, feed accelerator and screen.

- Simlpe & easy maintaince through service friendly design.

- Choice of Drive, Mechanical and Hydraulic Drives are available.

- Simple and Continous Operation.

- High yield,throughput and wash efficiency.

- No Spillage.

- Low Energy consumption.

- Eliminates manual handling.

- Simple & Low Cost Maintenance.

- Less Floor Space requirement.